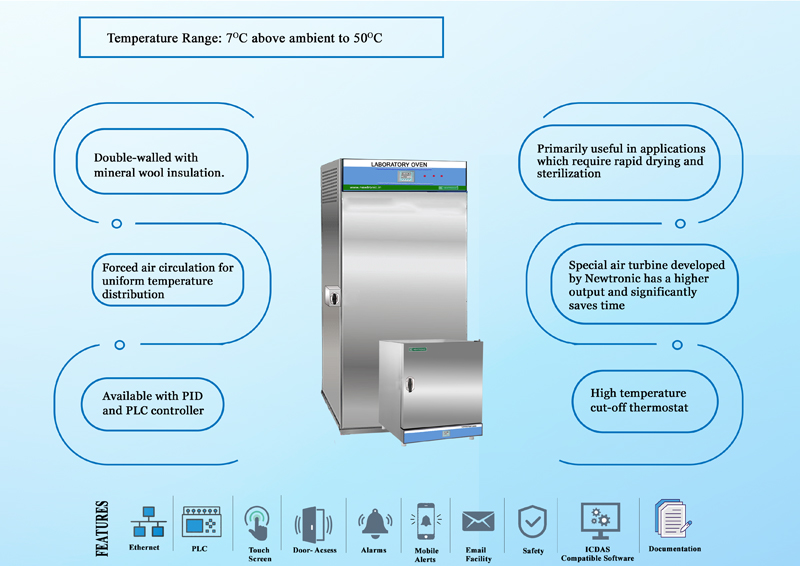

These units are primarily used in applications which require rapid drying and sterilization. Totally homogenous temperature distribution, rapid dynamic response and a special air turbine developed by us which has higher output have made it a genuine time-saving device.

They are also used to measure the loss on drying & are also referred to as LOD Ovens or Hot Air Ovens.

Units are equipped with Stainless steel trays, high quality PT-100 sensor & a microprocessor based controlling system with 2 line alphanumerical LED display. Alarms are generated for any deviations. The PID controller comes with an integrated timer functionality from 0 to 99 hours for ramp & soak functionality.

Stability (Reach In) Chamber

Stability ( Walk-In) Chamber

Freeze Thaw Chamber

Photostability Chamber

Ecotronic Chamber