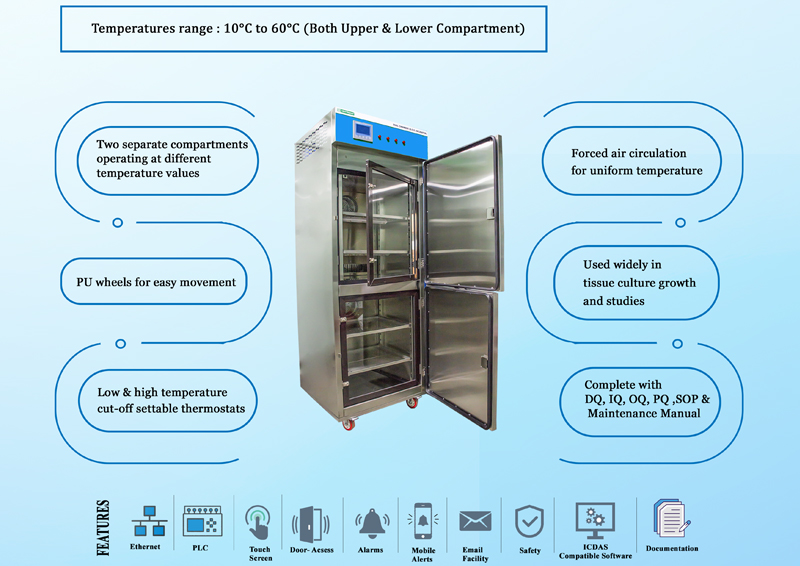

As part of our continous innovation program, we bring to you, the Dual B.O.D Incubator. You can use the two different compartments for two different temperature set values.

B.O.D. stands for Bacteriological Oxygen Demand. NEWTRONIC's BOD Incubators are ideal for the growth & storage of bacterial cultures, gentle incubation & conditioning and Media Preparation.

Media Prepartion & Culture growth at temperatures of 22.5°C (±2.5°C) & 32.5°C (±2.5°C) have become a standard practice in any Microbiology or ARD labs.

The chambers ensure consistent performance at any temperature within a range of 5°C to 60°C at an accuracy of ±0.5°C & at an uniformity of ±1°C.

The chambers are provided with a glass door for sample viewing & quick retrieval. They are connected through Ethernet to state-of-the-art 21 CFR Part 11 ready software that provide tools for viewing, trending, alarm management, audit trails, MKT & many other such features so as to comply with regulatory guidelines.

Stability (Reach In) Chamber

Stability ( Walk-In) Chamber

Freeze Thaw Chamber

Photostability Chamber

Ecotronic Chamber